- APPLY FOR SLOT

- Internal Users

- External Users

- SLOT BOOKING STATUS

Thermal Analysis (DSC, DTA, TGA, TMA) Laboratory

Phone : +91-3222-282493

Location : OB / FF / 12, CRF

Facilitator :

Dr. Titash Mondal, Rubber Technology Center

Email: titash@rtc.iitkgp.ac.in, Contact:+91-3222-283182

For Internal Users - Click Here to apply for Slot

For External Users - Click Here to apply for Slot

Objectives

1. Differential Scanning Calorimeter (DSC)

Type of analysis/characterization possible with the instruments: Typical applications include determination of melting point and the heat of melting; measurement of the glass transition temperature; curing and crystallization studies; and identification of phase transformations.

Recent works of significance done with the instrument/facility: Thermal stability of nanocomposites (isothermal and non-isothermal grain growth studies), glass transition temperatures of polymeric materials, curing of polymeric materials.

Type of projects in which the instrument can be useful:

New materials development

Understanding reactions mechanisms and kinetics

Understanding thermal stability of nano materials

2. Thermo-Gravimetric and Differential Thermal Analyzer (TG-DTA)

Type of analysis/characterization possible with the instruments: Reactions/phase transition temperatures, melting/fusion temperatures, heat capacity, crystallization temperatures, analysis of deabsorption and decomposition behavior, characterization of oxidation behavior, etc.

Recent works of significance done with the instrument/facility: Thermal stability of polymer nano composites, TG studies on the calcination of aqueous combustion synthesized metal oxide powders, analysis of reactions towards formation of new ceramic compounds, effect of mechanical milling on the reaction onset temperature of aluminum based nano composites.

Type of projects in which the instrument can be useful:

Research on developing nano materials, new alloys, intermetallics and ceramic materials

Develop understanding of degradation mechanisms

Interaction between different materials, formation of new phases, etc.

Crystallization behaviour of amorphous materials

3. Thermo Mechanical Analyzer (TMA)

Type of analysis/characterization possible with the instruments: Expansion coefficients, glass transition temperatures, softening temperatures, solid-solid transitions, melting behavior, swelling behavior etc.

Recent works of significance done with the instrument/facility: Sintering behaviour of nano composite materials, evaluation of thermal expansion coefficient for steel based composites.

Type of projects in which the instrument can be useful: Development of new materials such as nano composite

People

Dr. Titash Mondal

Facilitator

Rubber Technology Center

titash@rtc.iitkgp.ac.in

+91-3222-283182

Mr. Vishal Gupta

Technical Staff

Central Research Facility

vishal.gupta@adm.iitkgp.ac.in

82480

Equipment Details

Differential Scanning Calorimeter (DSC)

|

Thermo-Gravimetric and Differential Thermal Analyzer (TG-DTA)

Specification of the Instrument: Temperature range: 50 - 1500oC

Heating rate: Typical: 10oC/min, Maximum: 40oC/min

Crucibles: Alumina, Platinum

Manufacturer details:

Perkin Elmer Pyris Diamond TG-DTA

Purchase source (funding): Year of Installation: CRF Operating Grant

Year of installation: 2002

Thermo Mechanical Analyzer (TMA)

Specification of the Instrument: Temperature range: Ambient to 1500oC (Environment: N2) Heating rate: Typical: 10oC/min, Maximum: 100oC/minManufacturer details:

Perkin Elmer Diamond TMA

Purchase source (funding): CRF Operating Grant

Year of installation: 2007

Utility and Working Principal

Sample Details

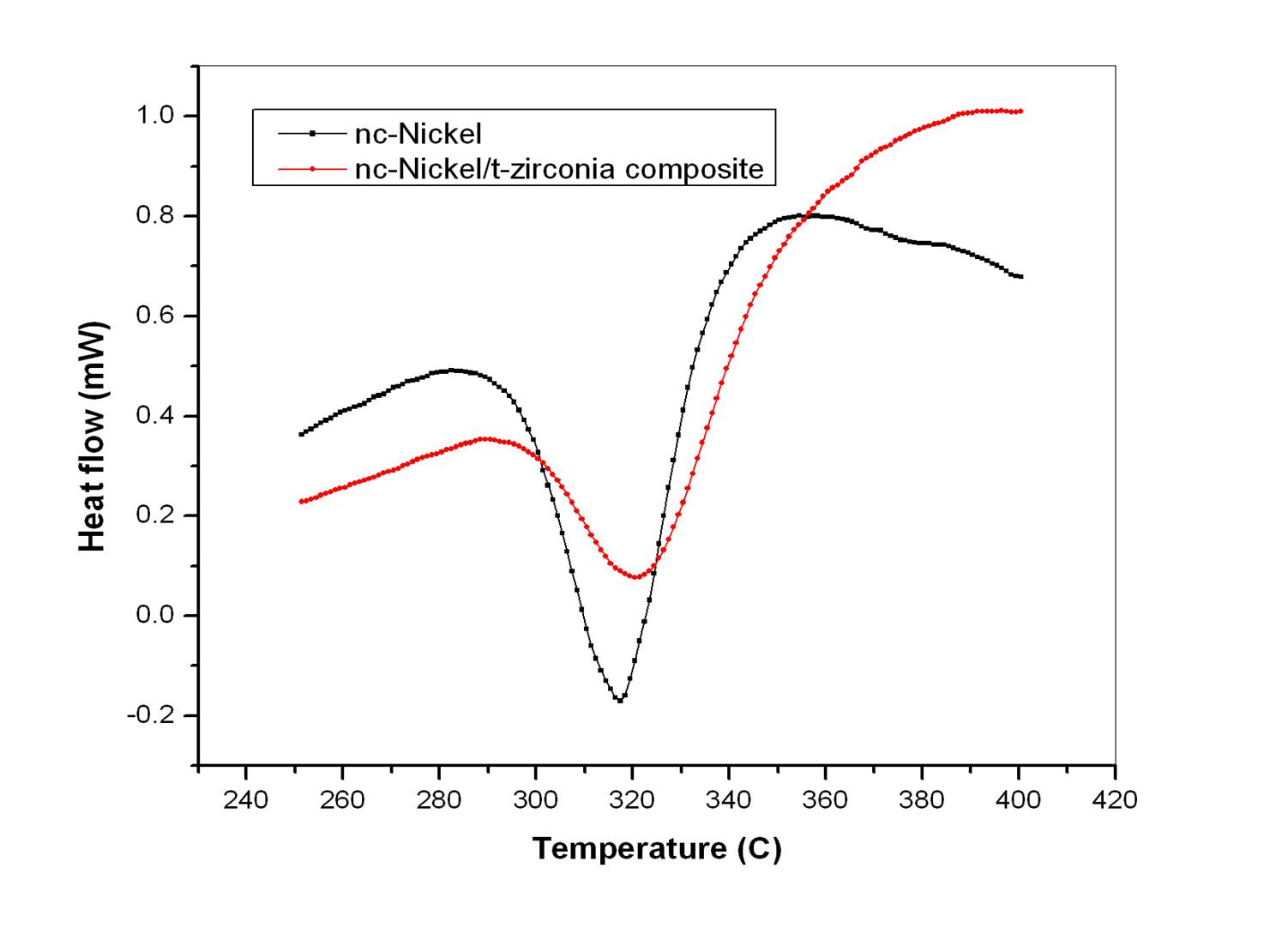

DSC thermograms showing grain growth for nanocrystalline nickel and nanocrystalline nickel/nanocrystalline ZrO2 nanocomposite at 20 C/min.

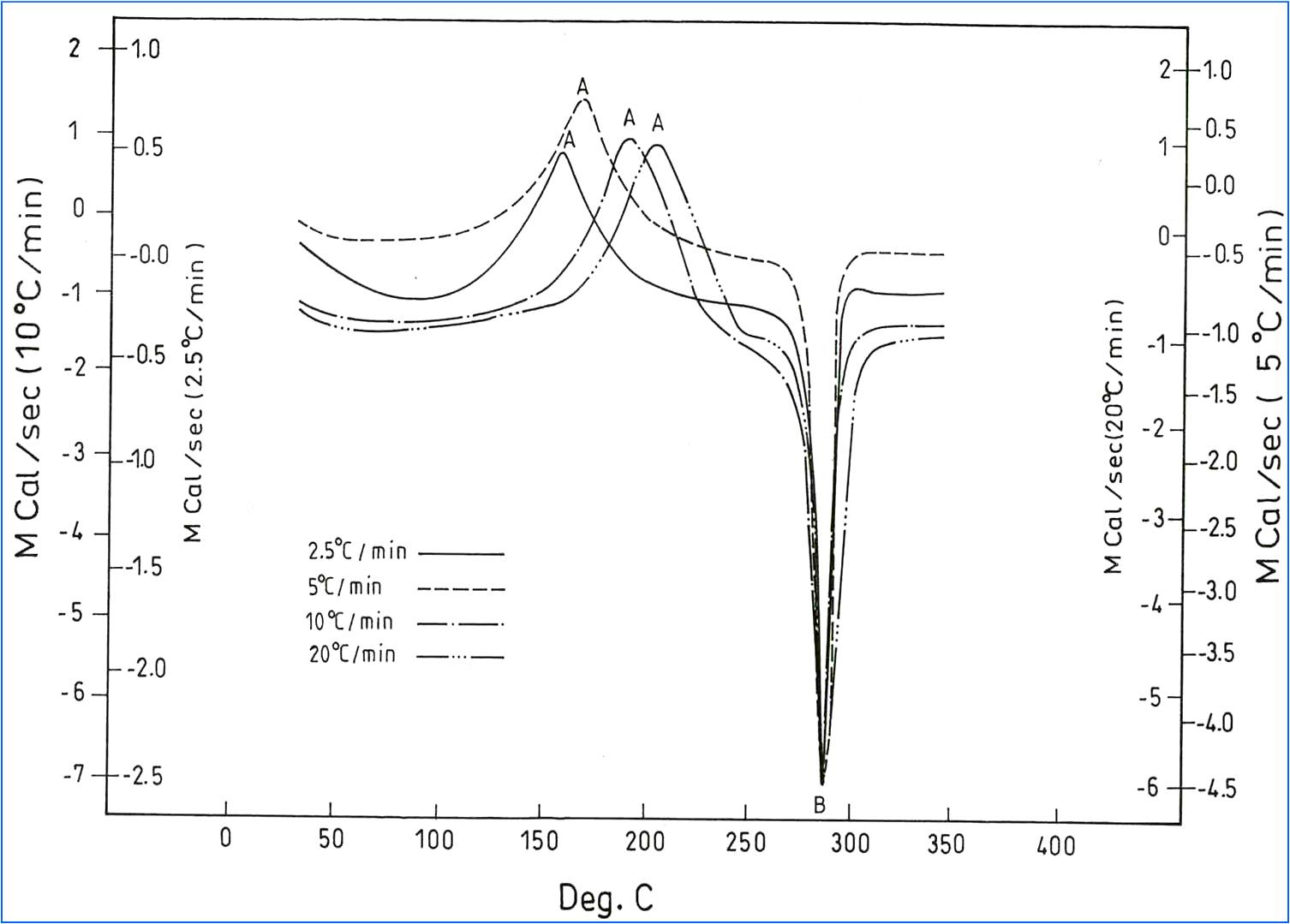

Non-isothermal DSC therrmograms of ZNi3 (70.32%Zn, 26% Al, 1.58% Cu, 0.05% Mg and 0.9% Ni) showing how the peak temperature for precipitation reaction is changing with the heating rate.

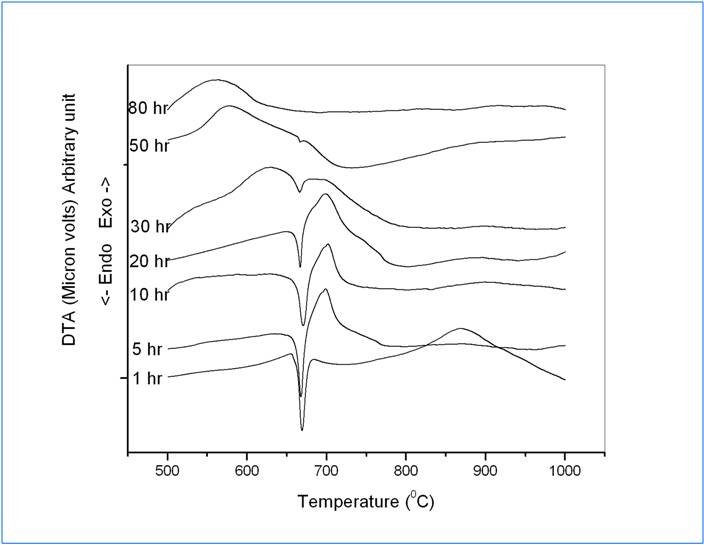

The DTA heating traces for the milled powders (Al-CeO2) showing how the exothermic peak for displacement reaction is changing with the milling time.

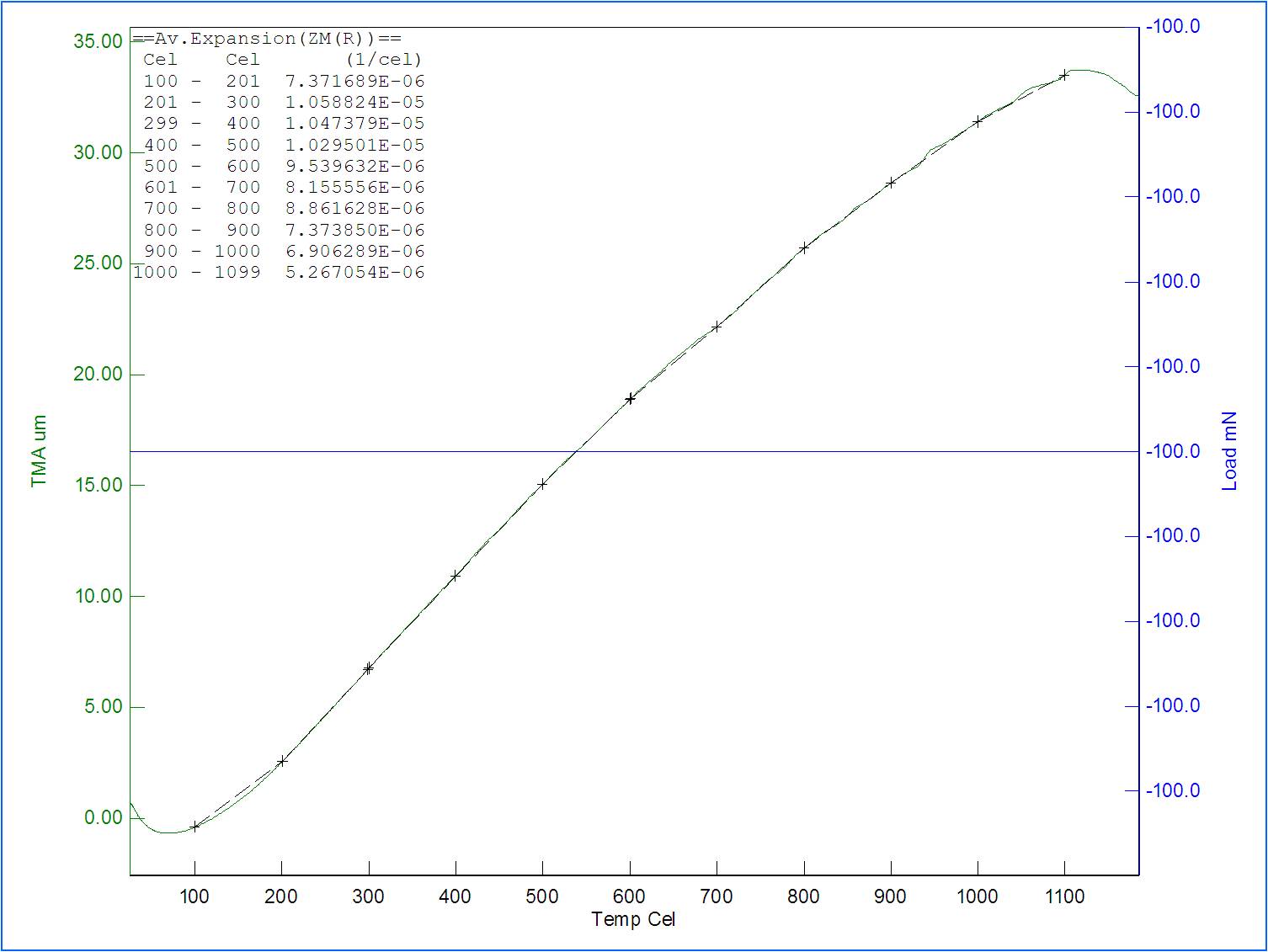

Measurement of the coefficient of thermal expansion (CTE) of the ultrahigh-temperature ceramics (UHTCs) showing variation of CTE with temperature.