- APPLY FOR SLOT

- Internal Users

- External Users

- SLOT BOOKING STATUS

Optical Microscopy and Mechanical Testing Laboratory

Phone : +91-3222-283244

Location : NB / GF / 8, CRF

Facilitator :

Prof. Koushik Biswas, Metallurgical & Materials Engineering

Email: k_biswas@metal.iitkgp.ac.in, Contact:+91-3222-283244

For Internal Users - Click Here to apply for Slot

For External Users - Click Here to apply for Slot

Objectives

Optical Image Analyzer Leica DMLM

This instrument was intended for use in metallurgical laboratories, particularly for quality control of steel cleanness and other microstructure measurement, but its usefulness in other fields soon became apparent. Early applications in the biological field were measuring the size of air spaces in the lung (to quantify lung damage) and counting silver grains in autoradiographs.

The universal illuminator is the heart of the Leica DM LM incident light microscope. The BF (brightfield, interference contrast, polari- sation), DF (darkfield) and Smith (quantitative polarisation) reflectors and the fluorescence filter systems are easily and conveniently switched with the 4-position turret plate.

People

Prof. Koushik Biswas

Facilitator

Metallurgical & Materials Engineering

k_biswas@metal.iitkgp.ac.in

+91-3222-283244

Equipment Details

Optical Image Analyzer Leica DMLM

Equipment Name: Optical Image AnalyzerModel Names: A) Leica DMLM B) Leica DMRX

Company Name: Leica (Made In Germany) Manufacturer details: Leica

Purchase source (funding):Indian Institute of Technology, Kharagpur

Order No:619/IIT/PO/F/EQ-161/(A)/CRF/05

Year of installation:August, 2006

Utility and Working Principal

What is Image Analysis?

Image Analysis is the science of making geometric and densitometic measurements on image from any source. Its main application is in quantitative microscopy, providing rapid, accurate and statistically significant data, replacing the traditional subjective methods.

Such measurements might be the volume fraction of various phases of an alloy or geological sample, the number and size distribution of contaminant particles filtered from air or hydraulic fluid, or the distribution of integrated optical density in the nuclei of stained cells.

Image Analysis first appeared as a readily available technique in 1963 with the introduction of the QTMA (Quantitative Television Microscope), designed by Metals Research Ltd., later to become part of Leica. This instrument was intended for use in metallurgical laboratories, particularly for quality control of steel cleanness and other microstructure measurement, but its usefulness in other fields soon became apparent. Early applications in the biological field were measuring the size of air spaces in the lung (to quantify lung damage) and counting silver grains in autoradiographs.

Since then, the techniques of image analysis have been applied in almost every field of science and technology from Anatomy through to Zoology, and have expanded to include image processing functions such as image filtering and enhancement.

What is Leica QWin?

QWin is Leica's Image Processing and Analysis toolkit running under the industry standard Microsoft Windows environment.

Note : If you are new to the windows operating system then we recommend that you learn the use of the Windows environment before attempting to use QWin.

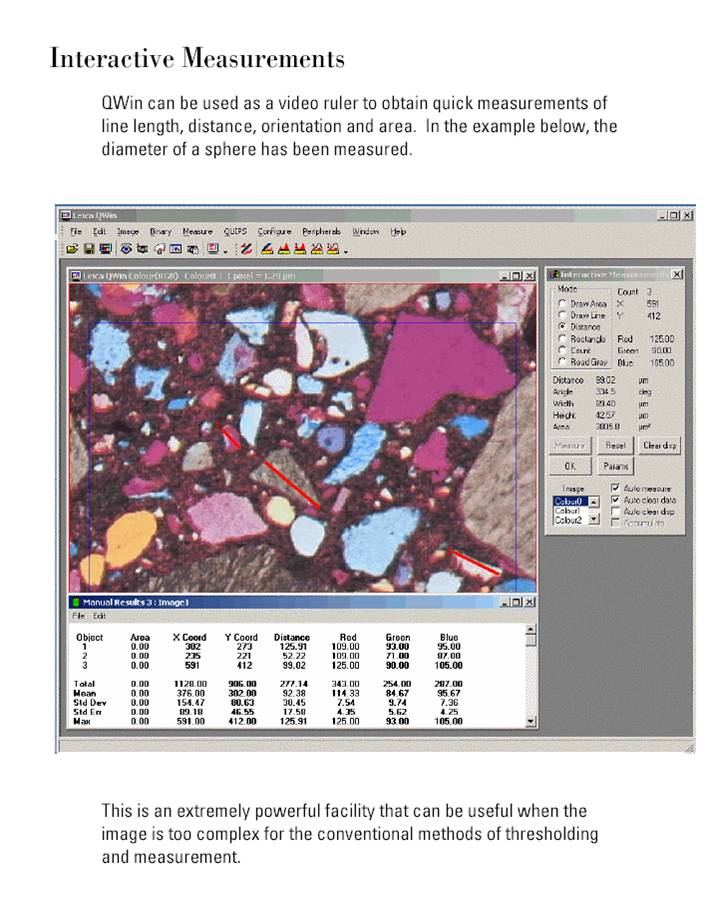

Leica QWin provides several classes of measurement ranging from interactive manual measurement of objects to fully automated 'Hands-off' analysis. Examples are :

- Planimetry of Length, Distance and Area

- Phase percent, Area Fraction and Volume Fraction

- Calibrated Densitometry

- Particle shape and size analysis

UHL-VMHT (VICKERS MICROHARDNESS TESTER)

The denotation "Micro hardness" derives from the field of hardness determination by means of an indenter entering the material to be tested with a specific load and dwell time. After removing the indenter, the produced imprint is measured and the "hardness number" calculated.

Sample Details

Sample Height: Maximum 30mm

Each and every type of sample

sample output of Optical Image Analyzer Leica DMLM

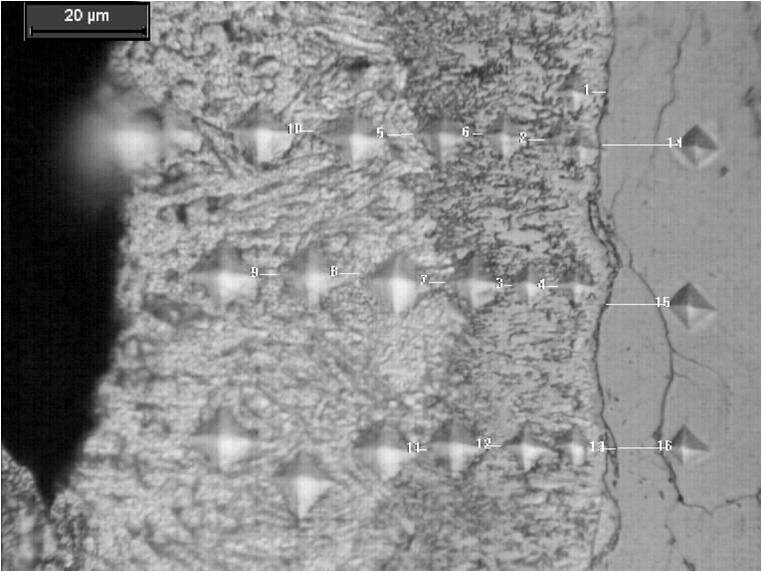

Imprints of Indenter

Image is shown directly on the touch-display